As critical as it is to build sustainable, updated infrastructure in growing communities, it’s equally as important to consider who is engaged in building these complex projects. Large undertakings, such as a water treatment plant Sundt is building in Oregon, have the potential to engage entire communities, bringing prosperity to many stakeholders by meeting the end goals of the project.

For Sundt Senior Project Manager Mike Neher, creating long-lasting partnerships with Oregon’s local business community has been a priority since Sundt moved into the market. “When our trade partners walk onto a jobsite, we want them to feel like part of the team, honor their expertise and come together to discover creative solutions to the problems we encounter,” he said. “We can tell our subcontractors that Sundt’s culture is different, but in the end, it comes down to our actions. We have to walk the walk.”

Mike explained that the subcontractor community is close-knit in Oregon; providing value and opportunities to grow and develop skills together is essential. “We’re all learning together on a jobsite. It’s not just about Sundt, but it’s about building a better construction community as a whole.”

At Sundt’s water treatment plant in Oregon, our team is building essential infrastructure for the surrounding communities. Keeping schedule and budget is top priority and requires the collaborative genius of everyone working on site.

Spyder Senses

Nick Bezates took over Bezates Construction from his dad and has over 20 years of experience in the industry. He attended Oregon State where he received an engineering degree and went into welding, also completing a degree in the trade. “Nick is a one-man show and does some impressive work, including much of the underground welding for the pipelines on site,” said Sundt Project Superintendent Jon Anderson.

With complex project phasing, and much of the work happening simultaneously, the team encountered a tricky situation when trying to install a dish head on one of the lines. The dish head “needed to be installed under a set of concrete scaffolding in order to test a line and keep the schedule moving. Since the tower crane couldn’t reach where the dish needed to be installed, options were thin,” Nick explained. “I was confident I could snake the dish head in with a spydercrane, although it would be tight.”

The concrete work above the pipeline could not be paused, so Nick turned to his spydercrane to help squeeze the dish head into the space. “This solution saved us a ton of time,” Jon explained. “It allowed multiple trades to work in the same area. Using this crane was something new for our team, and it was valuable for us to learn from Nick’s expertise.” Nick even welded a pick point onto the dish head so that the spydercrane could be used successfully. With collaboration, creativity and some cool equipment, the schedule was back on track.

“This is the most appreciated I’ve ever felt on a job. People I’ve never met come up to me on site, thanking me and telling me how appreciative they are for how hard I work. You’re normally a cog in the machine, a number on the spreadsheet, but the culture is really different at Sundt.” -Nick Bezates, Bezates Construction

Ensuring Seismic Resilience

Sundt’s transportation team of experts recently overcame another challenge on an aspect of the project that impacts the plant’s seismic resiliency. Along with two subcontractors, Alliant Systems and Petrichor Constructors, the team was able to come up with an effective solution that met the project’s goals.

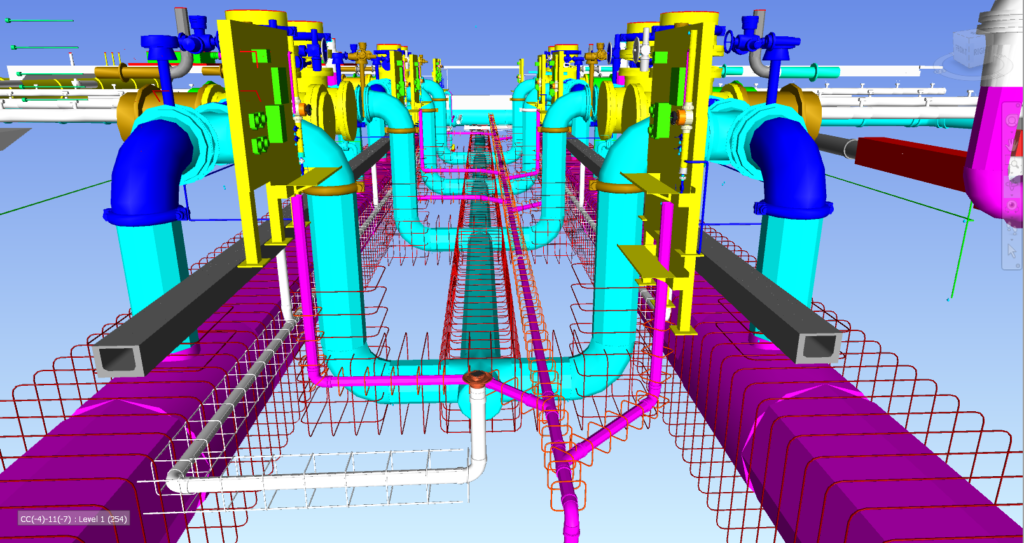

Sundt field engineer Garrett Hooker explained that there are several pipes under the filtration gallery, all of which called for separate concrete encasements with their own rebar cages. “In our BIM sessions, we realized there was a lot of conflict in the piping systems and the rebar for the systems. The reality was, it just wasn’t going to work out in the field when it was time to install the encasements. We went to Alliant and asked them if transitioning to one encasement that contained everyone’s pipes would be a possibility.”

Alliant Systems is a subcontractor on site responsible for the mechanical and plumbing systems, and some of the process piping systems. Alliant Senior Project Manager Collin Boudon explained, “we provided creative solutions to overcome this challenge which temporarily supported our piping within the monolithic encasement in filtration. Our embedded piping needed to be supported in a way that allowed several concrete pour lifts to be placed around our piping and trench drains without impact.”

“The Sundt team is very knowledgeable and well-staffed. Coordination has been efficient and productive; we have a great team out here on this project!”—Collin Bourdon, Senior Project Manager, Alliant Systems

Once the design was set, the Sundt team realized the schedule and budget could benefit from hiring local experts for this non-traditional formwork. Petrichor Constructors is a locally owned and operated contractor composed of journeyman carpenters and finishers. They brought in Petrichor to produce the concrete encasements for the pipelines, and the small, locally-owned company will continue to help with critical path work on the job.

“We appreciate Sundt’s safety culture. It’s not an image they’re trying to portray, it’s a culture they’re intentionally trying to build.” Mitch Timmins, Co-Owner and Superintendent, Petrichor Constructors

After coordinating with the subcontractors and armed with a BIM model, the team consulted the client with the new plan. “The pipes are encased because they have to be seismically resilient,” explained Nathan Griggs, Sundt Senior Project Engineer. “The design has to ensure protection against massive earthquakes. Being able to collaborate, not only with the subcontractors, but with the client to find a successful solution is extremely satisfying.”

According to Sundt Senior Project Manager Brian Van Vleet, the BIM model turned this process into successful collaboration because “it was visual; it showed all of the conflicts with the pipelines. Once all parties involved saw that, we were able to move on to finding the best solution.”

Valued Partnerships

Part of building prosperity in the communities we live and work in means creating trusted partnerships with local businesses. “Our subcontractors are brought on site as partners,” said Mike. “Building a positive culture with subcontractors and breaking down the barriers that often exist between subcontractors and the main contractor is a priority for Sundt.”

Sign up to keep up with the latest news about Sundt in the Northwest