Valued at over half a billion dollars, Salt Lake City’s new Water Reclamation Facility (WRF) is a massive public infrastructure project that will have wide-ranging benefits for the community. During the five-year rebuild, Sundt and joint-venture partner PCL Construction will use nearly 113,000 cubic yards of concrete and 16,500 tons of reinforced steel—almost double the amount of concrete and a third of the steel used in the Empire State Building. With project goals of Envision Platinum and LEED Gold, the new WRF is also designed to meet new environmental standards, while increasing ROI and reducing costs for ratepayers.

Building a green mega-project, however, doesn’t necessarily mean adding huge costs or complexity. Sundt|PCL crews have been recycling demolished concrete and using other local, more sustainable materials. Often, the most sustainable options are simply the most efficient or “leanest” to build. The ability to find these options—or, in some situations, to create new ones—is the mark of a capable builder. This is the case with our team’s recent self-perform concrete work on the WRF’s new Biosolids Storage Facility.

Sundt Concrete “Builds a Better Mousetrap”

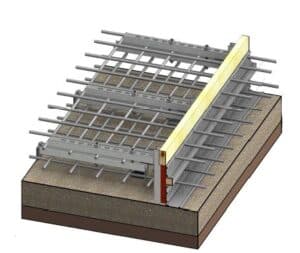

In early 2020, Sundt Concrete Superintendent Brady Terry saw the need for a better formwork method, so he decided to create his own. “In the past, we’ve always used particle board and form stakes to build our construction joints, which consumes a lot of lumber and stakes,” said Brady. “When you have hundreds of stakes protruding above the formwork, they get in the way of the finishers. They also create an impalement hazard, so you have to use hundreds of plastic bar guards.” Stripping and disposing of the formwork also took time and energy.

The solution? Remove the need for stakes and particle board altogether. “The new system uses perforated metal StayForm and Unistrut to hold everything in place,” said Brady. “When the placement is finished, you just remove the UniStrut bracket and top 2×4, and everything else remains in place. Then you can re-use the whole thing.”

The idea was met with enthusiasm by Sundt Vice President and Concrete Operations Manager Danny Gumm. Brady and Danny developed the drawings with help from Sundt’s VDC team and then tested the prototype with Sundt craft, and the WRF project was cleared as its maiden voyage.

“We’ve now placed over half of our slab on grade with this method, and it’s proven very productive while also minimizing material and waste,” said Brady. “We’ve completed the same amount of linear feet as the traditional method in about a third of the time.”

“On previous projects with similar scope, the form system would typically require two to three times more effort for the stripping process than building the system to begin with. It also made a huge mess, as 100% of the lumber/particle board would have to be destroyed in the stripping process. The clean-up alone would take quite a few man-hours and reduce productivity. This new process is faster, safer and better quality than what we’ve done in the past.”

– Sundt Vice President and Concrete Operations Manager Danny Gumm

JV Partner PCL Brings Shared Culture, Complementary Strengths

Coming off of a recent wastewater treatment project with Sundt in Arizona, PCL Construction was the ideal JV partner for a project the size and importance of Salt Lake City’s WRF. The facility will be able to process 56 million gallons of water per day and serve over 200,000 residents in the surrounding area.

“We came in with a strong relationship with Sundt’s Industrial Group,” said PCL’s Construction Manager Shayne Waldron. “Both companies are employee-owned, and that translates to shared values and a mutual desire to constantly improve our processes. This is evident in Brady’s work in concrete, and we see this dynamic from both sides throughout the site.”

As each company learns from and builds on each other’s strengths, a process of “iron sharpening iron” is taking place on this project. Self-perform crews including concrete, earth work, equipment setting and pipe setting are all a mixture of PCL and Sundt craft professionals, with each side bringing their own unique skills and best practices.

PCL’s expertise will be especially valuable as the team shifts its focus to other important scopes, including a 40-foot-deep, 7-foot-diameter tunnel that will run nearly a mile long underneath the site. This will be built using micro-tunneling, a trenchless construction method, and will serve as a main artery for incoming wastewater to be processed at the facility.

“PCL has proven experience in tunnel construction,” said Shayne. Currently pricing and performing constructability reviews on the tunnel, the team will soon be ready to tackle another major scope. “No doubt it will be challenging, but I know the team here has the combined ability to get the job done. So far, I’m really impressed with what we’ve been able to accomplish together—and I think our client is as well.”