Automated Material Transport Corridors for Cleanroom Facility

Features & Highlights

- All work was completed within a continuously operational manufacturing facility without interruptions.

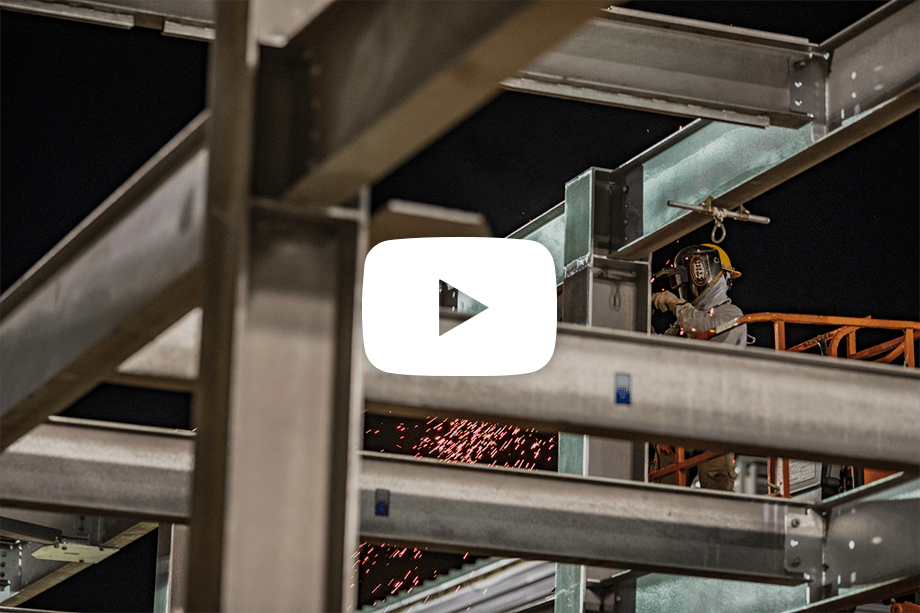

- The team constructed three elevated material transport corridors between fabrication buildings.

Project Overview

The team provided services for the design and construction of three elevated material transport corridors between fabrication buildings. The corridors allow for the transfer of products between two fabrication locations in a cleanroom environment, cutting down on manufacturing time and reducing contamination concerns.

Scope included corridor conversions in both fabrication buildings (Dirty to Clean), including re-routing of associated cleanroom systems and the construction of two material corridors that included a stocker and electrical building. Projects were completed following Class 10 Cleanroom ISO 14644-1 Standards.