The Sellwood Bridge project in Portland, Oregon achieved two important milestones last month when Sundt and joint venture partner Slayden Construction placed nearly 3,000 cubic yards of concrete at the foundations of piers 4 and 5, located in the Willamette River. The concrete pours represent significant achievements in the 47-month, $216 million project to replace the aging bridge with a new structure that is wider, safer and seismically sound.

The concrete milestones also represent impressive accomplishments in value engineering and ingenuity. Piers 4 and 5 are massive concrete structures comprised of reinforcing steel and 6000 psi concrete. Slayden/Sundt’s own workforce used specialized concrete placement techniques to control the excessive – and potentially damaging – heat that was created during the curing process.

“As fresh concrete hardens, or ‘cures,’ heat is generated as a byproduct of the chemical reaction,” explains Sundt Project Engineer Matt Fisher. “Due to the very large mass of concrete at piers 4 and 5, this ‘heat of hydration’ is generated faster than it can naturally dissipate, which could result in excessive internal temperatures and possible damage to the concrete.”

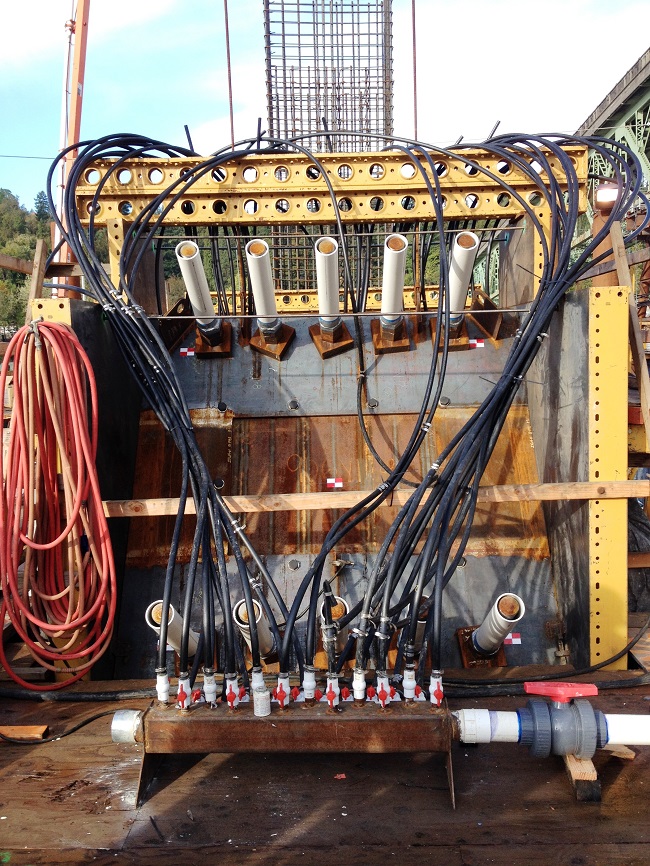

As a solution to this problem, the team designed an internal water-cooling system to remove the excess heat from the concrete. Water pumps, manifolds, intake screens, valves, flow meters and thousands of feet of flexible plastic water tubing were carefully placed throughout the concrete formwork. After the concrete was placed at the piers, cool water was continuously pumped through the plastic tubes, which in turn carried away the excess heat from the concrete. Remote temperature sensors were also placed throughout the fresh concrete to collect temperature data. As the concrete cured, and the internal temperatures climbed, this data was constantly monitored to confirm the performance of the cooling system and to ensure a quality product.