The summer and early fall have been busy for Slayden/Sundt as the joint venture reconstructs the 2,000-foot-long Sellwood Bridge in Portland, Ore. The team has been focused on constructing the in-water piers that will support the three new spans over the Willamette River. Each pier consists of four drilled shafts that are 10 feet in diameter and up to 176 feet below the river bottom (the river is approximately 30 feet deep).

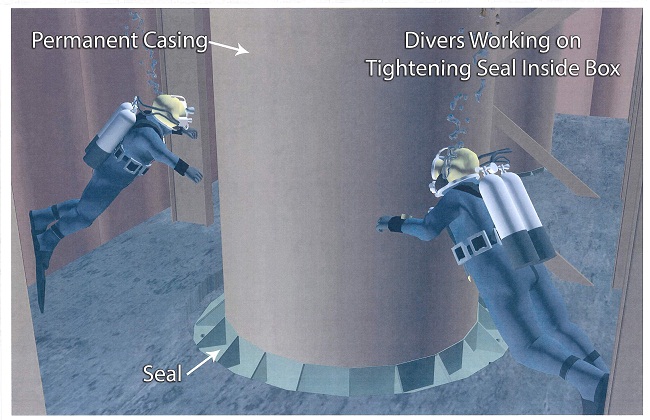

Environmental permitting constraints have left the team with a tight window to complete the drilled shafts and construct/install the perched boxes around the concrete columns. The perched box caissons will allow crews to complete the construction of the piers over the next nine months. They will be installed with cranes and pile drivers above water, and by divers below the water. Building Information Modeling (BIM) is being used to pre-plan the work thoroughly for maximum efficiency and safety.

The $207 million, heavy civil construction project involves replacing the aging Sellwood Bridge with an open steel deck arch structure. The project team is using an innovative “shoofly” (detour) approach to complete this complex project, which is explained here. This short video shows the successful bridge slide that took place last January.