Time and money are top priorities in construction, and parametric estimating tools can prove instrumental in the overall success of a project because they help create a precise picture of what a budget can buy during the initial conceptualization. Through the use of advanced parametric estimating software, what was once a laborious series of drawings and abstract conversations has become an efficient and succinct way to analyze initial and operating costs dependent on site orientation, systems and materials.

Time and money are top priorities in construction, and parametric estimating tools can prove instrumental in the overall success of a project because they help create a precise picture of what a budget can buy during the initial conceptualization. Through the use of advanced parametric estimating software, what was once a laborious series of drawings and abstract conversations has become an efficient and succinct way to analyze initial and operating costs dependent on site orientation, systems and materials.

Having been quick to adapt, apply and tailor these construction technologies for use in recent years, Sundt Construction has become an industry leader in parametric estimating. But not everyone understands the benefits. To help, Sundt’s resident expert Wayne Einbinder, vice president and director of the Special Projects Division, offers a look at 5 need-to-know facts about parametric estimating and how it is changing construction.

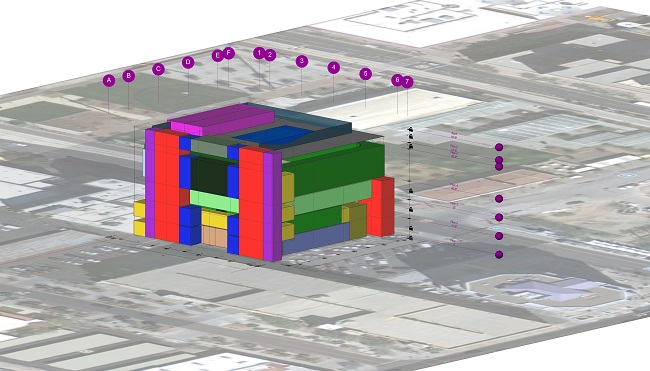

1. Parametric estimating can reduce the estimating process by 80 percent. It also provides more accurate cost-build estimates to be produced with less exertion involved. Tools like Dprofiler, software that Sundt employs in a unique fashion, allow for the creation of digital estimate models based on previously realized factors. A simple click and drag of the mouse within the 3D building model can produce precise estimates in real time.

2. Parametric estimating can produce more accurate results than detailed quantity take-offs during the early design phases. Prior to parametric estimating technology, each line item had to be laboriously measured, creating longer estimating timelines and greater potential for error as only what was drawn was estimated. Now with parametric estimating, all line items are intertwined by algorithms that work in real time so that when the height, footprint or number of stories is modified, the costs of all impacted line items are adjusted immediately.

3. Parametric estimating links to energy analysis models that allow for thoughtful design decisions at the outset vs. later when changes are no longer practical or cost-effective. Previously, most energy analyses occurred long after site orientation and massing decisions were locked in, which meant losing the greatest opportunities for energy analysis and adjustments. By contrast, parametric estimating works simultaneously with the energy-analysis estimate; therefore, when the changes affect a building’s energy use, Sundt can react quickly and factor in a facility’s initial costs as well as its lifecycle costs.

4. Parametric estimating is a powerful tool for doing “what if” scenarios. As changes can – and will – occur throughout a project, this technology offers insight into various potential scenarios. The real-time benefits allow the team to easily and quickly make changes and utilize concurrent price evaluations for timely and effective decision making.

5. Parametric estimating is an excellent communication tool. It gives the contractor the opportunity to sit down with the designer to review the assumptions and their impact – because estimates produce detailed information even though design isn’t yet detailed. Sundt uses historical information from specific projects types to provide a detailed cost estimate alongside a 3D building information model to combine the project’s design and cost analysis. This helps clarify various project elements in numerical and visual terms, offering all parties succinct insight into their tasks. With set design parameters and effective estimating, the team can establish a path for the project to remain on budget thereby eliminating any need for re-designs later in the process.